Team Organisation

Initial Inspiration

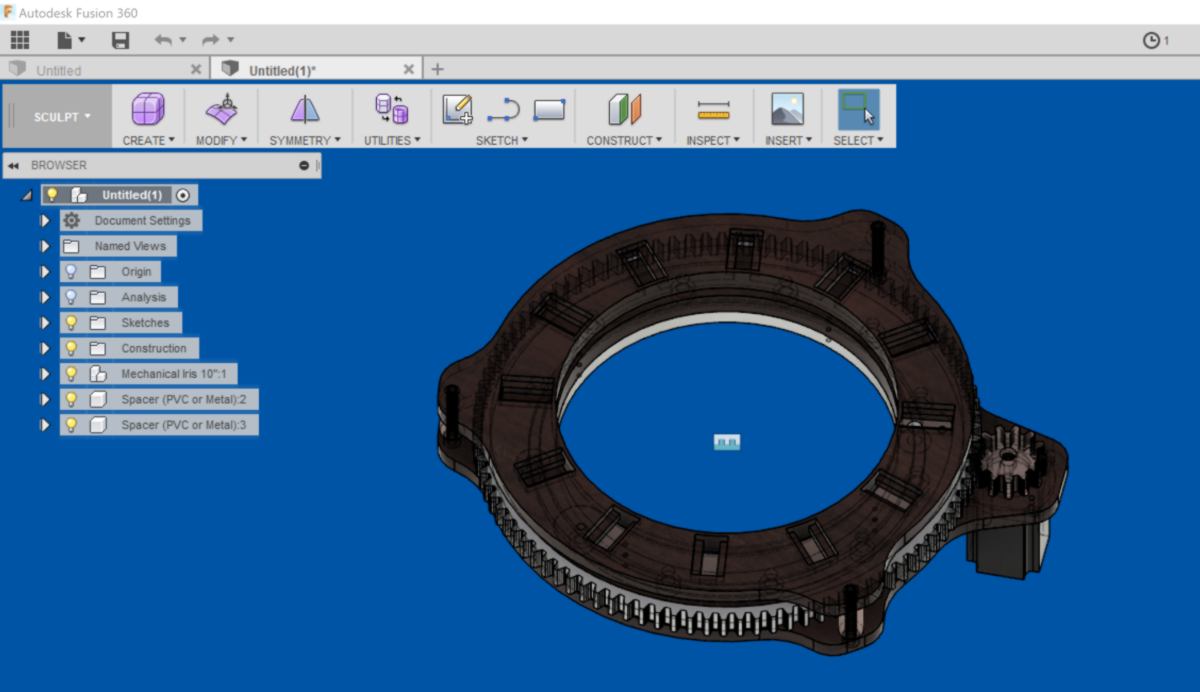

A week ago, some of us became obsessed about mechanical iris, and could not stop looking at how it is made, how it functions and possibly how to fabricate one in a lab. Well, it has become this week's theme now, and it has gone a little viral. Both Thais, Javi and Baptiste are keen to make one, and there is a big chance this will end up as a part of their final projects. So together, we are going to build a beautiful iris.

We have a look at a design available on the "make" website (small scale : 25cm wide) to determine how to get started :

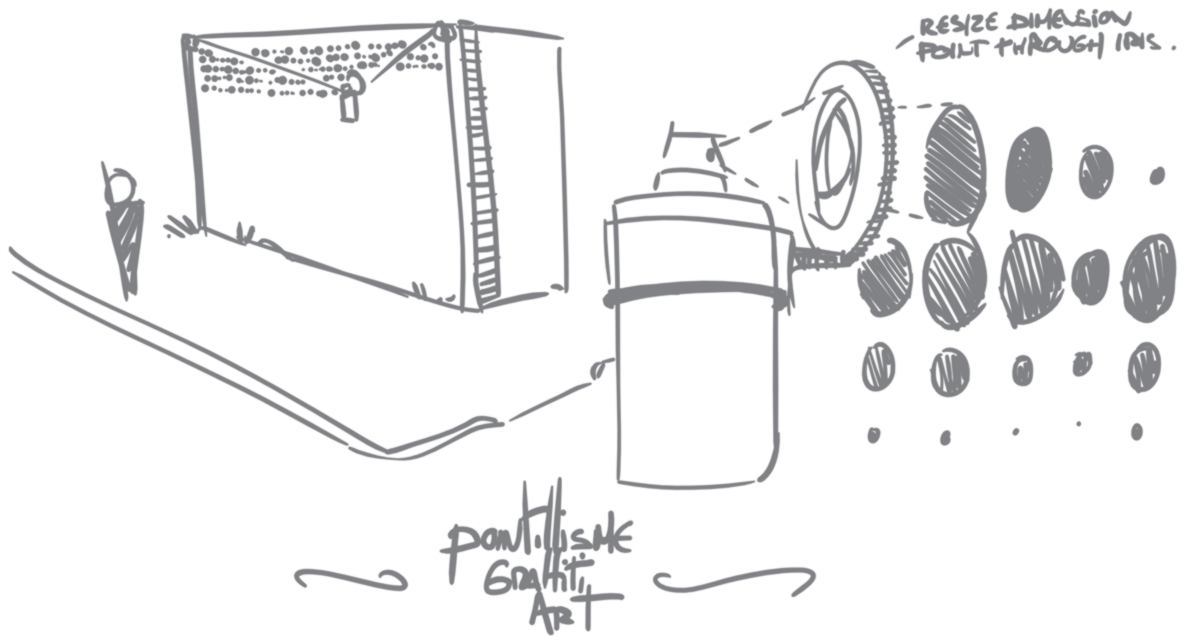

Some of us already consider a prototype in cadboard very fast based on that. But others are bothered since this design does not offers me the opportunity to learn about G-code. Some of us wonder : how to use this design and make good use of it to fabricate something a little more CNC-y? It comes together as we am flicking through some pictures :

This idea came to us while in class, so we silently show each other what we think about it, with no further explanations :

We all look at it and nod. It is baffling that we all understood the idea out of such a crappy sketch - it is going to be a good collaboration. For the purpose of this website, let us cast some light on the idea :

Brainstorming

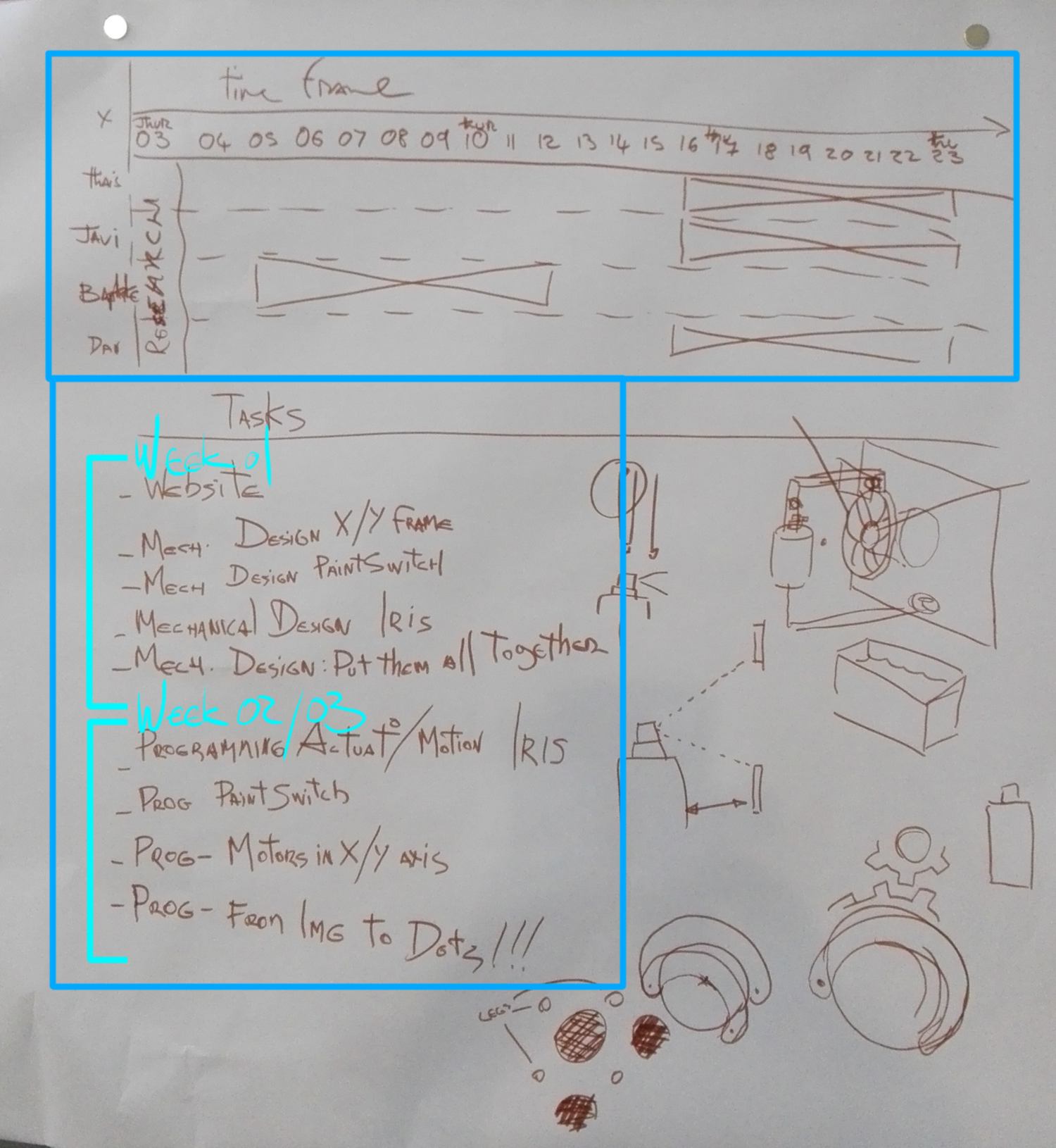

We set up communcation lines for our machine making group, creating a Whats App group. We then all gather around a white board and draft our next two-weeks project. Well in our case, since one of us is heading to Milan next week, we will keep working on it on week after the others will be done, which makes it a three-week project. Dan has joined us too. So it seems like everyone is happy about the spray machine, and here is our first draft :

We break down the tasks :

- the setup of the website and doumentation;

- the mechanical design of the X/Y actuator, based on the scriboo drawbot ;

- the mechanical design of the paint switch, based on a piston mechanism ;

- the mechanical design of thediaphragm, based on the cncrouter iris ;

- the programming of the actuator;

- the programming of the paintswitch;

- the programming of the iris;

- and finally, putting it together!

We also discuss type of material to be used according to the type of paint used, automatic washing system for the diaphragm (if necessary?), how the machine will be in contact with the wall without spreading the fresh paint over, using small wheel the size of the minimum distance between dots. We have a lot of research to do, so we agree on each reading about a specific topic.

Reality Check

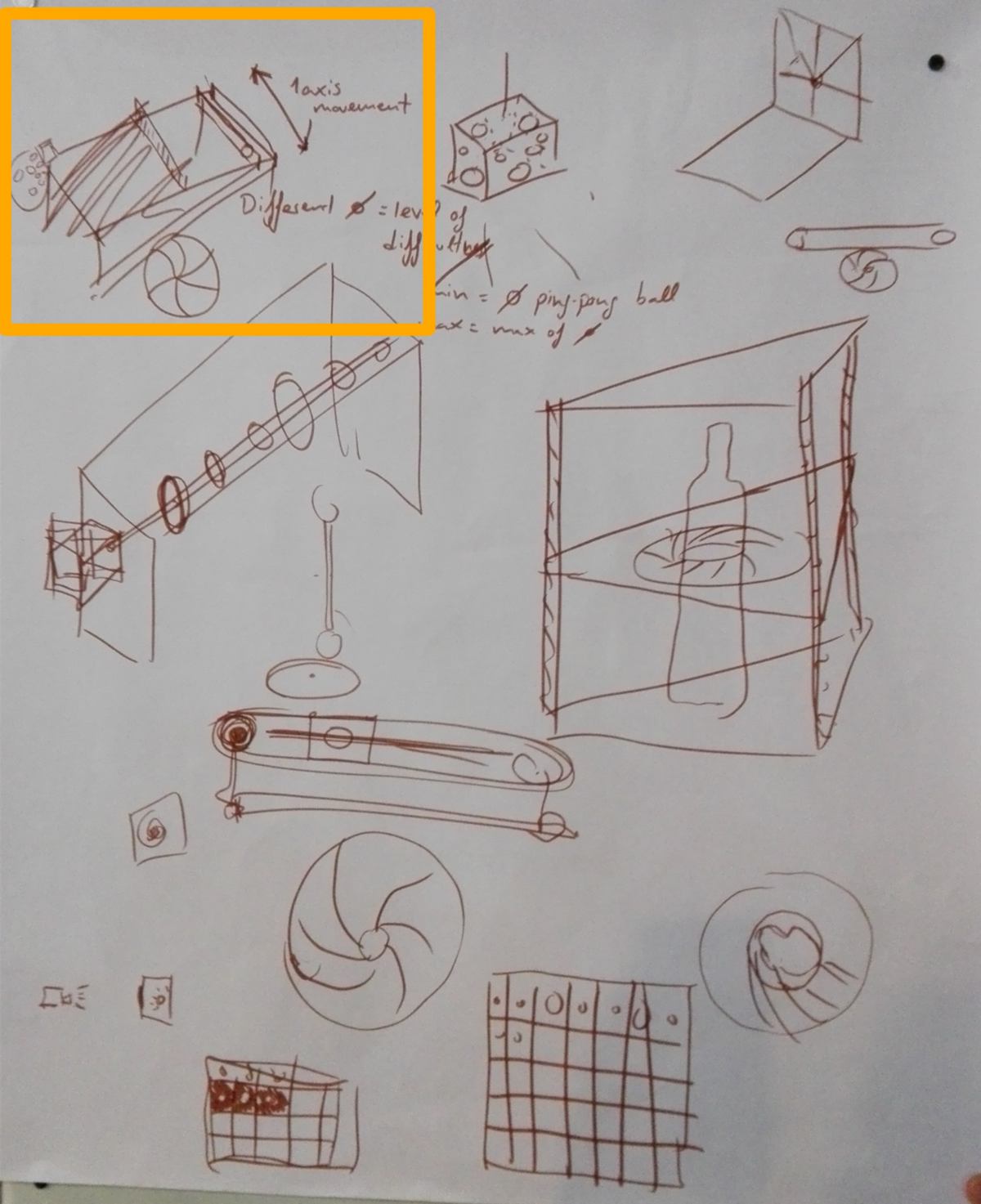

Then, One of us who could only arrive late finally walks in, and our instructor joins the conversation too. They both look at this plan like a recipe for disaster. We have placed the bar really high for all of us, completely green on machine making. One hour later, the whole project has changed. The focus on feasability is paramountand the project has been simplified greatly. The conclusion is the following :

Can you see the ping-pong table in the left-hand corner? Indeed, we are going to fabricate a game! the goal is to aim at the iris with the ball, which will move on one axis, from left to right. We all agree that it is better to begin with a simple project which can become more complex afterwards. It is important that no one feels too overwhelmed by the task - it is a group assignment after all. And, well, it is a ping-pong table, so it is techy, right, Kuka?

We separate the tasks : Javi and Thais are doing the research and design of the diaphragm, Baptiste is in charge of the website and further improvements when back from Milan, and Dan will focus on the mechanical axis. We are all set for the assignment!